Beauty companies know packaging can make all the difference in how well their products move off the shelves. From smart packaging to shelf-ready packaging, to packaging that leverages multisensorial and augmented reality, new primary packaging advancements abound nowadays, and because so much of purchasing decisions are based on the product packaging and presentation, packaging is critical to a good beauty product.

But new materials and design don’t only impact the consumer’s senses, however. They also can mean big changes to the production of products, and beauty brand owners can’t lose sight of important product aspects like the shelf life and safety that packaging addresses.

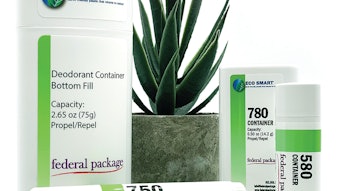

Primary packaging is only part of the picture. Brand managers may also get involved with decisions related to secondary packaging as well, which includes the cartons, wraps, dividers, films and other materials used to contain and ship the individual product units. Rising concerns for sustainability and lower waste among customers and stakeholders mean that both primary and secondary packaging must meet taller orders in terms of balancing multiple business and brand requirements and cost trade-offs.

How can so many complex factors be evaluated for the best result?

One way marketing and brand managers and owners can ensure an improved approach to the sourcing of their packaging solutions is through greater collaboration with procurement teams, many of which have access to new advances in sourcing technology that can take into account the preferences of brand managers and category owners, the purchasing team and suppliers—all helping lead to better packaging innovation.

Because of new web-based sourcing platforms and growing supplier acceptance of conducting business through software, advanced sourcing is no longer the domain of Fortune 500 companies only. It is now being adopted among the Global 2000 and sometimes even smaller companies.

So how can marketing and brand managers and owners collaborate with purchasing to improve margins and drive product innovation? Where once purchasing departments weren’t involved in such strategic spends as packaging, the push for cost-saving improvements, combined with the strength of today’s sourcing technology, is leading to an increasing collaboration between purchasing and brand teams. Brand managers no longer need to be in the dark about what the purchasing team is negotiating with the suppliers, but now can be part of the process using these types of sourcing solutions.

Beauty companies can quickly and easily create, launch, manage and modify sourcing events of any size, scale or complexity across a myriad of spend categories with new sourcing software options, allowing a team to streamline, automate and innovate through straightforward bidding events or enabling transformational strategies for larger or more complex spend needs. Further, sourcing technologies that utilize approaches such as “expressive bidding” give both incumbent and newly invited suppliers opportunities to communicate creative proposals and item options that buyers may never have considered, opening up new solutions and innovations in an increasingly exciting arena.

Case Study: A Meeting of the Minds

By way of an in-store branding example, one consumer goods company saved 45% on its in-store display spend, involving design, production and the assembly of the display materials. But the benefit was not just limited to dollar savings on material costs. Because this company leveraged sourcing technology that used the expressive bidding approach, they were able to optimize their supplier base while also improving the reliability and quality of display production and services.

The customer used advanced sourcing to design its online request-for-proposal (RFP) to capture component-specific information as well as options for turnkey solutions. Multiple product marketing groups were involved with the company’s corporate sourcing teams to uncover innovations and efficiencies. Plus, the time it took to analyze each sourcing scenario was reduced greatly. Scenarios that they evaluated included: “What if we give a 70% preference to incumbent suppliers?” and “What if we consider the alternative bid using cold-foil stamping on our high-end line?” The analysis process that once took days now took just a few seconds, consolidating the annual sourcing cycle. The use of sourcing technology made the collaboration effort between the internal team much easier, more efficient, and richer, as well as the work with the suppliers.

One concern that many business stakeholders raise is whether their suppliers (particularly long-standing incumbents) will be accepting of and find benefit in an online, technology-driven bidding process. With the right solution and the right training, suppliers can benefit greatly from the experience, and the business stakeholders now have a system of record of sorts for supplier bids and communication with suppliers.

Suppliers can be encouraged, as they were in this case study, to bid creatively in an online sourcing process. In the case study example, suppliers were invited to submit two sets of proposals—one identifying prices for full turnkey production (leveraging their strong alliance networks) and a second specification for only those product components and services they could supply directly.

This more complex set of data generated greater business insight when analyzed through the sourcing software’s scenario builder, allowing the customer to evaluate alternative materials and supplier-designed package offers, and to discuss with product marketing managers the cost impact of these options. Also, by letting suppliers bid based on their own strengths, the supplier relationships were strengthened, and millions of dollars were saved along the way.

Five Areas for Improved Strategic Sourcing

By following these guidelines when using sourcing technology, sourcing and brand and marketing teams can be on the same page, ready to tackle a beauty product packaging makeover:

- Define business preferences and requirements together and up front, to shape the supplier RFPs so the data collected can make later analyses better informed and any cost-benefit trade-off analyses more realistically evaluated. As one of the seven habits made popular by Stephen R. Covey states, “Begin with the end in mind.”

- Improve profitability by gaining a deeper understanding of the various cost drivers for different packaging scenarios.

Are supplier proposals as granular as they can be? From shrink films, stretch films, barrier films, bottles, caps, labels, corrugate and boxes, paperboard, and more, you can solicit cost-per-item and even other cost drivers such as freight costs, weight and other factors. And steps in the manufacturing process can be parsed as well, which allows brands to share with suppliers the points along the chain when they are more and less competitive. - Encourage alternative and creative proposals from suppliers. Ask them to put their best foot forward in terms of optional materials or production methods, packaged deals and conditional offers that bring deeper savings advantages.

Oftentimes, suppliers have innovative solutions they could suggest, but don’t have a good outlet within the RFP to express such alternatives. Sourcing solutions that utilize expressive bidding allows buyers to solicit reactive proposals from suppliers that include things like alternative materials, optional plant locations, alternative delivery time proposals, conditional offers and packaged offers. A robust analytics solution then delivers rapid, tailored scenario development to compare different award outcomes as different preferences and rules are applied. - Optimize the supply base. Find the right mix of incumbent and new suppliers, support supplier diversity initiatives and increase supplier competition to drive greater business benefits.

A request-for-information (RFI) can be a great place to learn more about suppliers you haven’t used before, as well as for an improved understanding of incumbent suppliers’ characteristics in terms of your business strategies related to overall corporate objectives. Even long-standing incumbent suppliers nearly always produce more competitive proposals when engaged in a new sourcing process. - Support sustainable sourcing initiatives through the supplier sourcing process. Packaging is an area ripe for addressing sustainability and waste-reduction goals. With advanced sourcing, you can get granular—soliciting data such as percent of recyclable content, carbon footprint estimates by manufacturing, equipment types used, weight for shipping/emissions analysis, and more. Then you can run analytics to create and compare scenarios that look at sustainability, environmental impact, cost drivers, supplier ratings, and more. This makes it easy to collaborate with business stakeholders to assess cost-benefit trade-offs.

Boxing Up the Scenarios

In the past, when setting up an RFP or RFI, sourcing teams would try to limit the amount of information that would be gathered, knowing that the later analysis would likely be too time consuming. But this upfront limitation is no longer an issue with newer sourcing technologies, paving the way for brand manager and purchasing team collaborations.

At analysis time, after receiving all of the suppliers’ bids, the possibilities become exciting. Sourcing teams can work hand-in-hand with brand managers and stakeholders to run and compare as many scenarios as desired. Scenarios a team might consider include:

- What is my low cost/unconstrained scenario?

- What if I award only to incumbents?

- What if I consolidated all the business for a particular subcategory?

- What is the cost of increasing the diversity of my supply base?

- What if I increased flexibility around delivery options?

- What if we tried item substitutions?

- What if we accepted these conditional offers or volume price breaks?

With so many options to consider from suppliers and such robust analysis available, beauty brand owners and stakeholders can make significant improvements to primary and secondary packaging of their beauty products. And all of these packaging benefits add up to a more solid, more competitive story in support of the brand.

Jennifer Sikora is vice president of marketing for CombineNet, provider of CombineNet ASAP e-sourcing software, used by five of the world’s top 12 largest CPG companies. She has been in the business software solution industry for 17 years, marketing products in the areas of e-sourcing, supply chain and data integration to mid-sized and Fortune 500 companies worldwide.