You have crafted your brand story, and you have the idea for the next best-selling product in the market—but how does this concept go from being an idea in your head to a product on your consumer’s bathroom shelf?

To Private Label or Not to Private Label

That is the question. The answer will very much depend on the expertise you have available to you.

If your team has chemistry and pharmacology expertise, it is recommended that you create your own formulations. This builds value in your business in the form of intellectual property, and ensures that your product formulation will be different from everything else on the market.

The downside is that this process can be challenging, lengthy and onerous. Creating a formulation from scratch will involve much testing, tweaking, and reformulating until you have something you like. Stability testing will be necessary once you have finalized the formulation, which will add to your launch timeline and costs.

If your team does not have the knowledge to create formulations, working with a turn-key manufacturer and selecting formulations based on a menu of options will be the easier way of proceeding. This is called private labeling.

The benefits to you is that the entire process is easier and quicker than creating a formulation from scratch. The downside is that you do not own your intellectual property, and that you are limited in your choices by the menu that your manufacturer has to offer.

The Third Way

The hybrid option is often the path taken by niche brands. This may be viable if you have specific ideas about what you want your formulation to be, do not want to do private label, yet do not have a team of chemists and pharmacologists in-house. This path requires a more involved partnership with your manufacturer, who also becomes your R&D lab. Hence, the importance of selecting the right manufacturing partner.

What to Look for in a Manufacturer

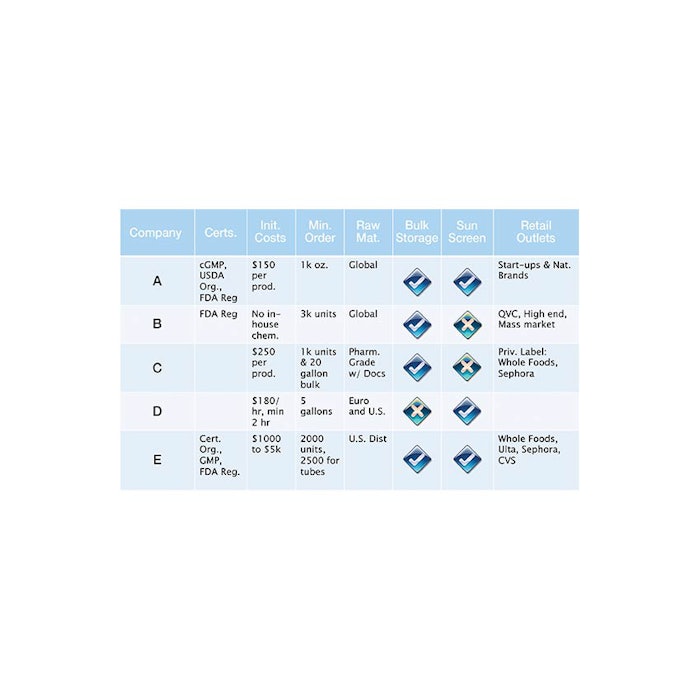

In 2013, when Alchimie Forever decided to switch its manufacturing from Switzerland to the United States, we interviewed a number of potential manufacturing labs. Our criteria were as follows:

- Certifications held

- Upfront formulating commitment/cost

- Minimum order size

- Sourcing of raw material

- Storage of bulk product for multiple fills

- Expertise in sunscreen formulation and regulations

- Packaging restraints

- Where products can be found (NDAs prevent the identification of brands)

- R&D expertise

- Location

In a recent conversation with Gogi Sangha, CEO and president of G.S. Cosmeceuticals (Livermore, CA), I found that his perspective mirrored ours when it comes to manufacturing criteria. When asked about the top concerns that a brand should consider when picking a manufacturer, Sangha replied:

- “That the manufacturer has historical knowledge and experience with the type of products that the client is looking to manufacture.”

- “That the manufacturer operates under a nondisclosure and confidentiality agreement.”

- “That the manufacturer is a cGMP facility (follows current good manufacturing practices).”

- “That the manufacturer has a robust quality department.”

- “That the manufacturer has sizeable R&D support, and technical transfer capabilities.”

- “That the manufacturer has the capacity and willingness to grow with customer.”

Sangha added, “It is extremely important that the manufacturer operate an R&D lab, as many issues can come up when formulating and manufacturing, especially when utilizing ‘natural’-based ingredients. An R&D chemist has an intimate and higher understanding of the chemistry behind the raw material, processing and formula itself; this knowledge is pertinent when developing any new formulation.”

A True Partnership

What does Sangha look for in a potential customer/partner? “That they have a marketing plan for the brand, that the brand is properly financed and has a good understanding of the types of products and raw materials they want to use in their formulas,” he explained.

The relationship between and brand and its manufacturer becomes a true partnership, a bit like a marriage, with ups and downs and easier times and harder times. The key is for the foundation of the relationship to be based on trust, common interests, and respect for each other’s expertise. Switching manufacturers is very challenging—even if you own your formulations—so picking the right one the first time will save headaches, heartaches and dollars.

Selecting Packaging Partners

Selecting packaging is another essential part of bringing your product from concept to reality. For most smaller brands, stock packaging will be the fiscally responsible strategy. Custom-made packaging, while more unique and offering more options and choices, is often prohibitively expensive.

When selecting a packaging supplier, Alchimie Forever looks at:

- Responsiveness of team

- Quality of product offering

- Breadth of product offering

- Minimum order size

- Printing options (silk screen, etc.)

- Sourcing options: made in China, made in USA, made of recycled materials, etc.

The best resources when looking for packaging suppliers are tradeshows.

Don’t Scrimp on Legal

Last but not least, following our industry’s regulatory guidelines is key. This means that there is one more partner in the process of evolving a product from an idea to a physical reality: a lawyer.

As a bootstrapped company, Alchimie Forever has always paid attention to costs and budgets. However, our FDA legal expert was one area where the company decided not to over-economize. We chose someone with significant FDA experience and who works in a large law firm. This was still less expensive than the alternative.

Our expert continues to advise us on labelling, claims, INCI listings and new regulations in the industry. The sunscreen regulation in particular has continually evolved in the last few years, and is particularly tricky to keep current on.

An additional resource to consider is the ICMAD “A Simplified Guide to Cosmetic Labeling.”* While this is not an alternative to legal counsel, this guide provides valuable information on the topic.

Keep in mind as well that different countries will have different regulations. If you plan on selling your products in Europe, for instance, speaking with an expert on European regulations and REACH will be necessary.

A Collective Effort

Dreaming up a product and creating a brand story that will resonate with the customer is just the start of any project. Transforming that dream and story into a reality involves a number of partners, ranging from manufacturers to suppliers to lawyers. Being able to find and work with these partners requires a budget and financing—which will be explored in the third article in this series.

_________________________________

Ada Polla ([email protected]) is the co-creator of the Swiss antioxidant skin care line, Alchimie Forever, which launched in the U.S. in 2004. Her strategic focus and implementation have yielded double-digit annual revenue growth for the company. Polla holds an MBA from Georgetown University, majored in art history and political science at Harvard University, and graduated magna cum laude with a Bachelor of Arts degree in 1999. She is also a Global Cosmetic Industry editorial advisor.

Footnote:

*www.icmad.org

Caption:

Make sure that your manufacturing partner meets all of your criteria.