Market-informed green innovation & the rise in biodegradability concerns

Any innovation is most impactful when it meets a current or emerging market need. When it comes to greener technology, this market need often includes solving for an undesirable Environmental, Health, & Safety (EHS) trait of existing functional technologies; take vinyl pyrrolidone (VP) copolymers for an example. These are copolymers of vinyl pyrrolidone and other vinyl monomers, e.g. acrylic acid or eicosene.

Another example is acrylates, which are copolymers of acrylic acid or acrylic acid ester monomers. These categories of copolymers often serve as film-formers for cosmetic and sun care formulations. The concern of microbeads in our oceans and environment has been apparent for a few years, and that concern now extends to other microplastics and non-biodegradable substances. Many common copolymers, including VP copolymers and acrylates copolymers, fit into the non-biodegradable substances category. Environmentalists and conscious consumers alike are concerned of the impact these chemistries have and are seeking to avoid such ingredients. The Clean at Sephora standard does not accept many acrylates, evidence that this concern is entering beauty’s mainstream.

The era of the conscious consumer demands a new way of innovating

What if it were possible to make a film-former that can serve the same functional need, but does not have the same environmental concerns? With green chemistry, there are ways to maximize more EHS attributes. The INOLEX natural polyester platform accomplishes exactly this, resulting in 100% natural and biodegradable film formers. Refer to Figures 2 and 3 to follow the example of LexFilm™ Sun Natural MB.

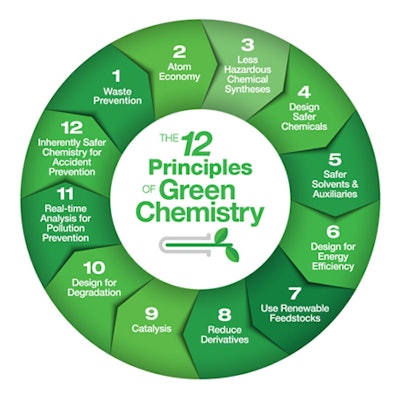

A significantly more sustainable life cycle (SLC) is achieved by designing with green chemistry (GC) and including additional consumer and environmental considerations.

SLC Step 1: The beginning of the ingredient’s lifecycle is non-GMO, plant-based feedstocks. Coconut, castor and RSPO Mass Balance certified palm are used to make this eco-friendly film former. Feedstocks account for one of twelve considerations in green chemistry (GC Principle #7).

SLC Step 2: No solvents are employed in this manufacturing process, accomplishing GC Principle #5. The only by-product is water, preventing pollution (GC Principle #1).

SLC Step 3: This ingredient is a 100% active, eliminating the shipment of water. This doesn’t relate to a specific green chemistry principle but it does improve the sustainability of the supply chain.

SLC Step 4: Step 4 is where the Sustainable Life Cycle transitions to benefiting the finished goods manufacturer and the consumer. The pourable liquid format is easily used in manufacturing finished goods and improves the manufacturer’s energy efficiency (GC Principle #6).

SLC Step 5: Consumer use refers to functional performance in addition to user safety (GC Principle #4). The product has to perform, or consumers will reject it and the sustainability benefits will be underutilized.

SLC Step 6: Referring the above issue with traditional film formers, biodegradation and persistence in the environment are import considerations to today’s conscious consumer. GC Principle #10 is achieved in the INOLEX polyester platform.

Combining the Principles of Green Chemistry with Sustainable Life Cycle thinking is a design process that creates greener technologies. LexFilm™ Sun Natural MB is entirely plant-based, readily biodegradable, and is nonpersistent in the environment. It can be used to boost SPF and achieve water resistance in sun formulations as well as improve smudge-proof makeup.

Combining the Principles of Green Chemistry with Sustainable Life Cycle thinking is a design process that creates greener technologies. LexFilm™ Sun Natural MB is entirely plant-based, readily biodegradable, and is nonpersistent in the environment. It can be used to boost SPF and achieve water resistance in sun formulations as well as improve smudge-proof makeup.Disclaimer:

The above paid-for content was produced by and posted on behalf of the Sponsor. Content provided is generated solely by the Sponsor or its affiliates, and it is the Sponsor’s responsibility for the accuracy, completeness and validity of all information included. Global Cosmetic Industry takes steps to ensure that you will not confuse sponsored content with content produced by Global Cosmetic Industry and governed by its editorial policy.