Hydrosome Labs, an innovative startup, has developed a natural and chemical-free process improving the power of water through the emerging science of ultrafine bubbles. The uses for the technology continue to grow with applications across multiple verticals and processes.

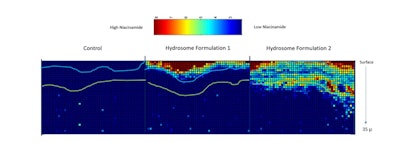

A study from TRI Princeton and Hydrosome showed Niacinamide delivery into the skin was significantly improved vs. the control substance (deionized water).

Nick Jackowetz, Chief Scientific Officer at Hydrosome Labs, said the study shows the technology can "significantly enhance the efficacy and performance of ingredients in cosmetics to maximize consumer benefits, from wrinkle reduction to increased firmness, elasticity and hydration." A previous study showed Niacinamide with Hydrosome H2O penetrated 2-3 times deeper into skin samples vs. Niacinamide and deionized water.

- Its stability of up to two years has not been previously recorded in literature. The closest shelf life in the emerging nanobubble category is four to six months.

- The technology is highly sustainable with no added chemicals or consumables as part of the patented process, and it takes very little energy to operate.

- It can eliminate the need for other chemical-based penetration enhancers — simplifying formulas and ingredient statements, as well as potentially reducing the skin irritation issues some of those chemicals may cause. Formulators can create a cleaner formula with improved performance.

The study found Hydrosome H2O dramatically increased hydration compared to deionized water. Jackowetz concluded that for the first time, the technology transforms water from a filler to a “super-carrier,” delivering nutrients to hard-to-reach areas with remarkable speed and efficiency.

Another study found that Hydrosome Labs technology is potentially ushering in a new era of precision fermentation. According to the new research, the technology is poised to solve multiple problems faced in precision fermentation, a process that involves the customization of yeast and/or bacteria to produce specific molecules for use in a wide variety of applications, including cosmetics, food, ingredients, biofuels, industrial enzymes and pharmaceuticals. This new technology also has the potential to help solve a global industry bottleneck in fermentation capacity and equipment, allowing for the production of dramatically higher yields in the same size or previously unsuitable tanks.

“It’s truly exciting to see how easily the ultrafine bubbles produced by Hydrosome’s technology integrated into our pilot scale reactors and showed immediate benefit to microbial growth,” said Brian Jacobson, associate director of Strategic Operation at the Integrated Bioprocessing Research Laboratory (IBRL) at the University of Illinois Urbana-Champaign. “While there have been significant advances in synthetic biology resulting in a tremendous number of new products capable of being made through fermentation, we have seen very little innovation in the fermentation process or equipment to assist in scaling these discoveries. This technology has the potential to positively impact the economics of new products in a wide range of industries and can also be applied to existing processes or retrofit last generation fermentation equipment currently unsuitable for these new products,” said Jacobson.

Hydrosome’s preliminary evaluation at IBRL showed that substituting Hydrosome H2O for regular water in an example fermentation resulted in:

- 2X faster cell doubling rate;

- 25% less overall fermentation time; and

- 2X higher peak cell biomass.

The bottom-line benefits to the industry include faster fermentations, higher yields, lower energy and nutrient inputs, lower labor costs, higher efficiencies, no added chemicals and no regulatory impact.

Disclaimer:

The above paid-for content was produced by and posted on behalf of the Sponsor. Content provided is generated solely by the Sponsor or its affiliates, and it is the Sponsor’s responsibility for the accuracy, completeness and validity of all information included. Global Cosmetic Industry takes steps to ensure that you will not confuse sponsored content with content produced by Global Cosmetic Industry and governed by its editorial policy.