The Lenzing Group has announced the launch of its upgraded lyocell shortcut fibers by Veocel for the flushable market.

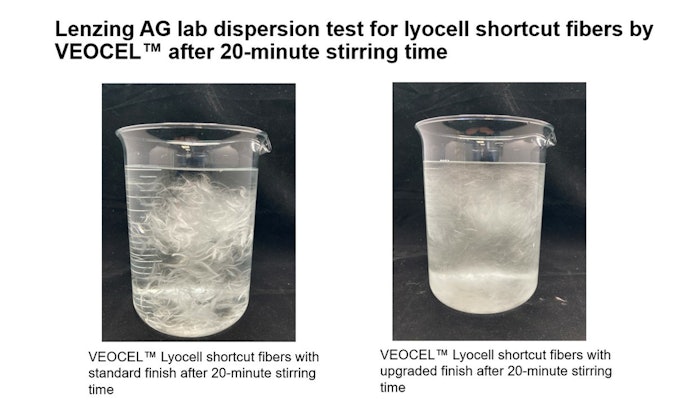

The upgraded lyocell shortcut fibers not only have high dispersibility—which make them ideal for use in flushable wipes—they also have an upgraded finish.

They can be purchased from Lenzing’s production site in Mobile, Alabama.

The new finish of the fibers offers protection against mechanical stress at commonly used water temperatures such as 0°C to 40°C during the wetlaid production process, which helps to avoid the creation of fiber lumps during the opening and dilution of fibers in preparation tanks.

The fibers are also offered as carbon neutral.

Albaad, one of the largest wet wipe manufacturers in the world, used the new lyocell shortcut fibers for its Hydrofine product.

Claudio Zampino, commercial director, specialty applications for global nonwovens business at Lenzing, said, "We’re always looking for new ways to innovate and improve the performance of our fibers in the flushable market. It is important to engage in continuous discussions with value chain partners to address their challenges and needs as we drive innovation in the nonwovens sector. With 27 years of experience producing lyocell shortcut fibers, we will continue to keep leveraging our extensive research labs to offer customers the best premium lyocell shortcut fibers possible.”

Jacob Heen, CEO of Albaad, said, "We are proud to cooperate with the global Lenzing group in developing improvements for lyocell fibers and bringing new innovation that enhances our Hydrofine product and improves the production process. Our unique Hydrofine product, which is considered a breakthrough in the flushable market, is based on these upgraded fibers that help to increase production efficiency, reduce the level of waste and improve customer satisfaction. Collaborating with Lenzing’s R&D team was a valuable experience that provided both sides with great knowledge. Albaad is committed to innovation, to reduce the industry’s carbon footprint, and to ensure continued improvement of our products’ performance."