With networked production processes and the use of automated manufacturing systems, companies of all sizes—be they small, medium-sized or corporate—can increase their flexibility, minimize costs and increase profits. The FRICKE-Multiplex ensures precise dosing, controlled filling processes and batch traceability to ensure consistent product quality, formulation accuracy, compliance with quality standards and end-user safety.

Achim Richter, Sales Director Dosing Technology, FRICKE Abfülltechnik GmbH & Co. KG

Achim Richter, Sales Director Dosing Technology, FRICKE Abfülltechnik GmbH & Co. KG

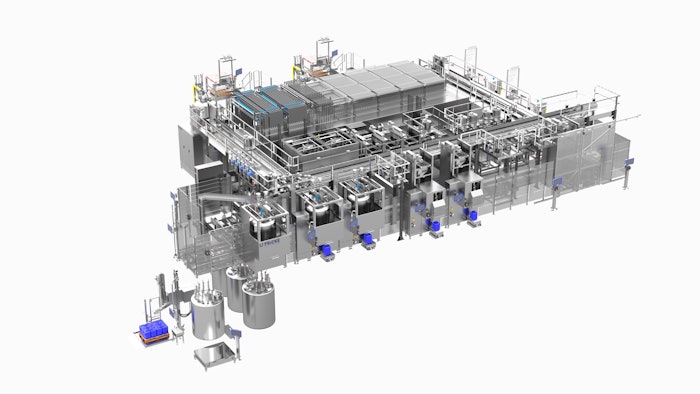

The dosing and filling of perfumes and flavors often presents manufacturers with challenges in terms of efficiency, precision and quality. FRICKE Abfülltechnik GmbH & Co. KG, the mechanical engineering specialist from Minden, Germany, has developed an automated system in close cooperation with experts from various fields that enables efficient and precise dosing as well as reliable filling of perfumes and flavors. The focus was not only on increasing performance, but also on improving the working conditions for the employees. With the help of the innovative automated FRICKE-Multiplex system—which is protected by a utility model (DE 202023102541.2)—the efficiency, precision and quality of production processes can be raised to a new level. By using industry-specific software solutions (MES and BI systems), FRICKE enables smooth production processes, uniform machine control, comprehensive data evaluations and more freedom in order processing. From process analysis to commissioning, the company delivers a turnkey solution from a single source.

Increased Efficiency Through Intelligent Process Flow

The FRICKE-Multiplex system optimizes the entire production flow by linking the individual dosing and filling systems with each other. This enables a seamless and efficient transfer of the mobile FRICKE-Multiplex containers—which are also protected by a utility model (DE 202023102540.4)—from one station to the next. The intelligent process flow minimizes bottlenecks. Waiting times are minimized, which significantly increases overall productivity. In addition, the system reduces the need for manual intervention, and makes the handling of aggressive and flammable chemicals safer.

The system ensures high product quality. Precise dosing and controlled filling processes guarantee that the individual perfume and flavor components are mixed in exactly the right quantities and ratios. Consistent quality and recipe accuracy are logged for compliance with quality standards and increase safety for the end consumer. With integration of all production processes like automatic and manual dispenses, mixing, filtration, filling, and cleaning a significant reduction in turnaround time for next day delivery is reached.

Increasing Flexibility and Adaptability

Thanks to the modular design, individual components of the plant can be easily exchanged or added to meet special production needs on an application-specific basis. This allows users to respond quickly to new market trends and customer requirements without having to make large investments in new production equipment. The plant is equipped with a container shuttle system that efficiently transports the mobile mixing tanks. The system controls stationary large tanks as well.

By integrating all process steps into an automated overall process, productivity was significantly increased. Precise dosing and filling with batch tracking and a mixing tank history with documented cleaning improves product quality. In addition, the high level of automation has a positive effect on the working conditions and employee satisfaction.

Liquids and powders are precisely dosed with FRICKE dosing systems for the perfume and flavor industry.

Liquids and powders are precisely dosed with FRICKE dosing systems for the perfume and flavor industry.

Potential for Further Applications and Industries

The FRICKE-Multiplex is a profitable future technology not only for the perfume and flavor industry, but also in other industries where dosing and filling in batch processes play a central role. It demonstrates the transformative potential of Smart Factory and enables companies to make their manufacturing processes smarter, increase flexibility, minimize costs and continuously improve quality.

The Benefits of FRICKE-Multiplex

• Efficiency Increase & Quality Improvement: Optimized production flow, precise dosing, controlled filling, and batch traceability ensure consistent product quality and recipe accuracy.

• Productivity Increase and Reduction in Turnaround Time: Automated processes lead to higher productivity, especially in industries where dosing and filling play an important role.

• Flexibility & Adaptability: Modular design meets specific production needs and enables rapid adaptation from batch sizes small to large.

• Secure Skilled Labor: Reduction of manual and monotonous tasks improve working conditions through automated processes and increase employer attractiveness.

• Product Individualization: The integrated technology enables flexible product individualization according to customer requirements.

• Process Safety & Automation: Precise control and production monitoring ensures process sequences.

• Transformation Process: The FRICKE-Multiplex enables adaption to the digital era and opens up new business opportunities for long-term competitiveness and innovation.

FRICKE valve technology for high dosing accuracy and flow rate with reliable protection against cross contamination.

FRICKE valve technology for high dosing accuracy and flow rate with reliable protection against cross contamination.

Contact Us

For more information on FRICKE systems, visit https://www.frickedosing.com/en/fricke-multiplex.

Disclaimer:

The above paid-for content was produced by and posted on behalf of the Sponsor. Content provided is generated solely by the Sponsor or its affiliates, and it is the Sponsor’s responsibility for the accuracy, completeness and validity of all information included. Global Cosmetic Industry takes steps to ensure that you will not confuse sponsored content with content produced by Global Cosmetic Industry and governed by its editorial policy.