Complementary to "The Shape of Things to Come." this Q&A with Julie Vergnion, product manager, Rexam Personal Care Division, and Matt Croson, vice president, member services/communications, Packaging Machinery Manufacturers Institute (PMMI) explores material trends for 2010 and beyond.

Any discussion of materials trends is ultimately part of the larger goal: brand building through innovative packaging solutions. Materials, processes, knowledge of end-user needs and ergonomics are all part of the equation. Today, consumers around the world look for an overall “better” packaging experience, in terms of function and aesthetics. There is a worldwide move towards premiumization of packaging. Every year, the bar is set higher. It becomes increasingly critical for brand owners facing important global launches to collaborate with innovative, single-source suppliers that can help shorten supply chains, provide international launch support and help build brand equity.

What packaging materials trends began to emerge in 2009? What trends impacted the market in 2009 and what trends will continue to emerge in the year ahead?

JV: There is growing demand, worldwide, for new (and greener) materials. The quest for eco-friendly materials will be an ongoing trend and new materials will be unveiled in 2010. Further, there is a growing trend toward premiumization of personal care product packaging, in markets around the world.We note with interest the recent Natural Aquarela line repack for the Brazilian brand’s lipsticks and compacts that addresses demand for ever-increasing levels of package sophistication and uses environmentally-friendlier materials. Developed in conjunction with Natura at Rexam’s Jundiai, Brazil, facility, the packaging solution includes sophisticated use of PMMA on the compact covers, silk screening on the lipstick mechanism’s sleeve and further customization of a WPC (wood plastic composite) formula that renders the wood particulates visible and appealing and allows injection flow.

Another example of worldwide premiumization: the Oriflame, one of the world’s fastest growing direct sales beauty products companies, has selected Rexam’s airless and neutral Prodigio, the 100% recyclable lotion pump designed with patented CleanPoint technology, for its North For Men Total Age Control Cream. This latest assignment builds upon our Oriflame relationship and underscores the briskly accelerating importance of packaging that imparts high perceived value in the world’s emerging markets. Oriflame is an industry innovator that launches 900 products annually, sells in 61 countries and derives most of its €1.3 billion in annual sales from eastern Europe and Russia.

MC: The single largest trend that we saw in 2009 and predict will continue into 2010 was the continued emergence of new materials that respond to sustainability-oriented objectives. One example of these new materials is polylactide (PLA), a biodegradable plastic derived from renewable resources like cornstarch and sugarcane.

2010 is going see greater demand from brands for verification of the sustainability claims that many packaging suppliers make about materials. There is a possibility that we could see a push for industry-wide standards to regulate claims and ensure transparency.

Are there new materials expected to emerge in 2010? How do these trends evolve?

JV: In terms of eco-friendly materials, the tipping point has been reached where our customers and consumers understand the importance and desirability of such materials. And this intersects with the worldwide trend to premiumization of packaging. And it’s why the latest eco-chic fragrance from Tous (the Spain-based luxury brand known for its environmental and fair trade policies) has selected our 100% recyclable Sof’n’Touch dispenser for the mini-version of its new H2O fragrance. We created the Sof’n’Touch with only three parts(bottle, applicator and cap) for the ultimate in consumer appeal, timeless aesthetics, production efficiency and value. Fragrance application is by touch, achieved by capillary action, for precise placement of the fragrance, with no waste.

Given its earth-friendly attributes, classic elegance and proven functionality, the Sof’n’Touch was a logical choice for the mini-version of H2O. The mini-product communicates all the aesthetic values of the brand, is in congruence with their respect for the planet and is a cost-efficient packaging solution as well.

Another example is our just-launched Crystal Transparency material, perfect for samplers, which are increasingly important in new product launches. In addition to its remarkable clarity and visual appeal, this material offers manufacturers startling clarity and beauty, as well as cost and manufacturing efficiencies, and is available on all Rexam standard samplers, including Sof’n’Touch, Mini-Mist and Sofistic’s. It offers all the aesthetic allure of glass, yet without the cost. It is lighter than glass, for reduced transportation costs, and is tough enough to reduce filling line breakage. In fact, use of Crystal Transparency cuts development time, as compared with glass. Plus, supply chain management is enhanced, since we offer both the pump and bottle (both recyclable, with less energy needed, as well).

MC: From a materials perspective, we believe the focus on bio-based materials will be the biggest news-maker in 2010. Driving this will be the evolving impact of biodegradable materials such as PLA, as well as Coca-Cola’s recent announcement of the company’s goal to adopt bio-based containers.

Outside of new or emerging materials, we believe that the lightweighting packaging through redesign and material reduction will be another important topic carried into 2011.

Do these trends grow upon themselves yearly? Are the 2010 trends direct outcomes or progressions of 2009 trends? How do these trends evolve? What longer-term trends can be projected from the 2010 trends?

MC: The packaging sector is evolutionary in nature. The introduction of new resins and materials prompts machinery manufacturers to adapt equipment as needed, which can take time in order to guarantee efficiency. No one wants to risk a product launch failure resulting from incompatibilities on the packaging line. So, while existing trends may foster new innovations in materials and package design, all are ideas until they can be manufactured. Then, it’s time to launch.

What are some of the technical advances that have allowed expansion in the use of certain materials for beauty packaging?

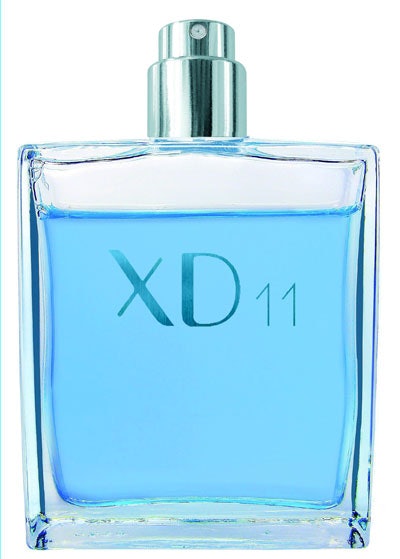

JV: Because there is a strong trend of premiumization of mass market packages, high luxury brands must find new ways to keep their rank: they do that by offering added convenience, enhanced functionality and attention to details, like the smoothness of a lipstick mechanism or the quality of a closing click feature. With fine mist dispensing, for example, there is an art of spray and actuator development. We continually study the performance of our pumps, in order to enhance the spray characteristics and quickness of priming. We have an R&D team dedicated to the study of canal geometry, calculation of flows and turbulence, in order to constantly offer pumps that can handle the world’s great fragrance brands. Superior spray and ease of priming enhances the end-user experience, as with the XD-11 fine mist pump, now being used around the world.

In lipstick packaging, a good example is the Chanel Allure Lipstick case with its unique opening-closing mechanism: the very sleek package looks seamless until a gentle push on the golden top reveals the lipstick, which is ‘stored’ in the same way after usage; this case is equipped with the Rexam R2000 mechanism, which offers dry, non lubricated operation and is designed to protect even the more delicate formulations. Another example of exciting prestige product decoration is our work for Dior, using Opalis, a surface treatment developed with this customer. It is a painstaking process of metal spraying over the entire surface, resulting in a sparkling, gemlike effect.

Further, this premiumization of mass-market product packaging results in greater demand for quality materials, decoration elements, finishes, etc. The Maybelline Mineral Power case, for example, opens both on the side and vertically, an exciting, unique feature that enhances the end-user convenience. When the case is turned sideways, to the right, the mirror position housing the puff is revealed. Opening the top section reveals the powder, which can then be easily applied. The design also allows for a shade-evident top lens, heightening convenience and retail appeal.

Then, too, is the impact on packaging derived from the popularity of natural and or organic formulations. These are inherently more fragile; also the general trend is to limit as much as practical the preservatives and anti-bacteria additives in all formulas, organic or classical. Such formulations require packaging with higher protection levels, like higher barrier property, airless functioning and extreme closure features to prevent the formulation from oxidation.

MC: Currently, there is a strong demand for rigid containers as companies continue to prioritize the protection of their products across the supply chain. However, I expect to see more of a shift to flexible packaging. We’ve already seen this taking place in the food and beverage sectors and the cosmetics industry has begun to follow suit, with many brands packaging lotions in tubes.

How do material trends in beauty complement or reflect other, larger, trends? Or, how are they influenced by larger trends?

JV: Our business is innovation-driven. We are part of the daily lives of consumers: every day there are multiple interactions with our customers’ products and our collaborations on packaging solutions. Brands are built through ongoing product differentiation. Product packaging is a large part of the equation. Our knowledge of demographic changes, our ability to create ergonomic advantages, all help our customers keep consumers engaged with the brand.

In makeup, for example, we note many new trends, such as volumizing mascara, anti-clumping formulations, water-proof mascara and more. Working in partnership with our customers, we will continue to work to drive innovation in this sector and develop packaging solutions that build brands. Innovation in mascara has been mostly driven by the applicator over the past few years, to the point that applicators, whether traditional twisted-wire-and-fiber brushes or more recent molded-polymer applicators, have become extremely efficient and produce spectacular makeup results. It is uncertain how much further we’ll be able to sustain this trend to more-than-perfect makeup results. However, we believe that package convenience has been to a large degree left aside in the "Quest For The Holy Applicator." There is significant room for improvement in package functionality and ergonomics. Also a new generation of materials are making their entry in waterproof mascara containers by offering high barrier property materials that are more affordable and easier to process.

How do material trends trickle down from wider consumer packaged goods segments to impact beauty packaging?

MC: Material trends tend to spread from one market segment to another when it’s practical for multiple uses and different manufacturing lines. At Pack Expo shows, we commonly see instances where, for example, a company needs a solution for beverage packaging but prefers a solution used by a food brand and, ultimately, finds a way to apply it to their product.

The stand-up pouch is a great example. We first saw it used to package Capri Sun beverages. Two years after that product package launched, stand-up pouches were adopted for a wide range of products. The borders that separate packaging innovations among different markets are porous. It’s entirely possible that stand-up pouches will penetrate the beauty market one day.